Last Updated on July 20, 2025 by David

Understanding the Vital Importance of Limestone in British Architectural Heritage

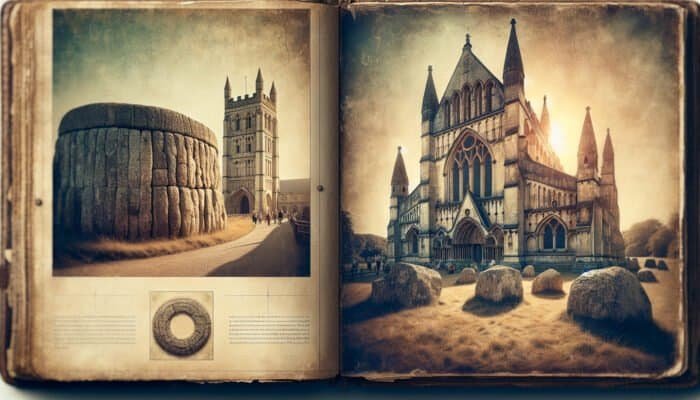

Limestone is a cornerstone material in British architecture, integral to the construction of numerous storied buildings that have withstood the tests of time for centuries. Its unmatched durability combined with its stunning aesthetic appeal renders it a favored choice for various constructions, from grand cathedrals to quaint cottages. The historical role of limestone in the UK is profound; it has not only sculpted the architectural framework but has also enriched the regional cultural identities across the nation. Landmark examples, including the celebrated Cathedral of St. Paul in London and the ancient stone circles found in Avebury, exemplify the enduring beauty and resilience that limestone bestows upon British architecture, affirming its status as an extraordinary building material.

Diving into the Historical Impact of Limestone in Construction Practices

The significance of limestone in the construction of historic buildings throughout the UK is undeniably immense. During the medieval era, there was a marked increase in the use of limestone as builders sought materials that not only could withstand the ravages of time but also provided unique aesthetic qualities. Much of the limestone used in esteemed structures like Westminster Abbey and the Tower of London was sourced locally. This practice minimized transportation costs and infused a level of craftsmanship that resonated with local significance, establishing a deeper connection between the architecture and its natural environment.

As these exceptional buildings have undergone various renovations and restorations over time, the methods used to preserve their limestone features have continuously evolved. For instance, during the Victorian period, there was a resurgence in limestone quarrying, which allowed for the creation of magnificent stately homes embellished with intricate limestone carvings, showcasing the remarkable versatility of this material. The influence of limestone on architectural styles during this era is evident, reflecting notable characteristics of Gothic, Classical, and Renaissance designs, all of which extensively utilized limestone to craft compelling visual narratives.

Professional Recommendations: Premium Products for Daily Limestone Care

Discovering the Various Types of Limestone Available in the UK

The United Kingdom is home to an impressive variety of limestone types, each showcasing distinct characteristics that render them suitable for diverse construction purposes. One especially notable type is the Jurassic limestone found in the Cotswolds, renowned for its warm honey color and frequently utilized in the construction of buildings and boundary walls throughout the area. This specific limestone not only boasts visual charm but is also remarkably durable, making it an ideal choice for outdoor uses where longevity is paramount.

Another prominent variety is Portland limestone, primarily extracted from the Isle of Portland in Dorset. This limestone is distinguished by its fine grain and uniform texture, earning its place in some of London’s most prestigious structures, including the iconic St. Paul’s Cathedral. Every type of limestone exhibits unique traits that cater to different architectural styles and environmental contexts, showcasing the UK's rich geological tapestry and the adaptability of limestone as a premier building material.

The Imperative of Regular Limestone Maintenance for Longevity

The necessity of routine maintenance for limestone structures throughout the UK is paramount. Due to its porous nature, limestone is particularly susceptible to weathering, staining, and erosion over time if not meticulously maintained. Neglecting these surfaces can threaten their structural integrity and visual allure, potentially leading to costly repairs in the future. Regular honing and restoration of limestone surfaces not only enhance their appearance but also extend their lifespan, significantly reducing the risk of structural decline and preserving the beauty of these historical masterpieces.

In regions marked by high pollution levels or harsh weather conditions, the urgency for maintenance becomes even more critical. Urban settings often expose limestone to acid rain and various pollutants, which can hasten the deterioration process. A comprehensive understanding of the specific maintenance needs of local limestone varieties is essential for preserving not only the physical structure but also the rich historical narrative tied to its existence, ensuring that future generations can appreciate these remarkable edifices.

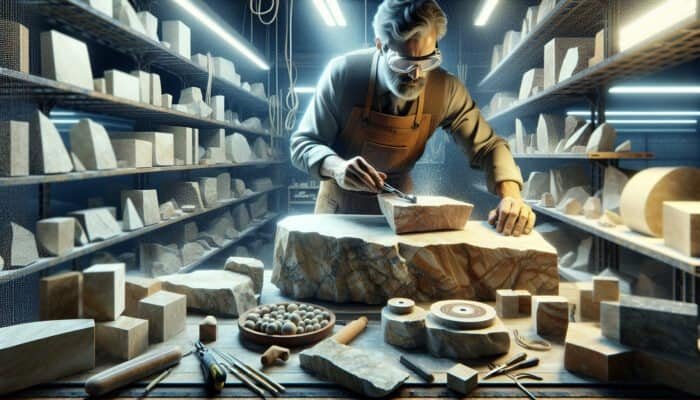

Mastering Expert Techniques for Honing Limestone Surfaces for Exceptional Results

The honing of limestone is a critical procedure that refines its surfaces, amplifying its aesthetic characteristics and preparing it for subsequent treatments and protective coatings. This intricate honing process requires skilled artisans and specialized tools to ensure the highest quality results. For homeowners and professionals alike, grasping the subtleties involved in honing limestone surfaces is essential for achieving a flawless finish that unveils the material’s inherent beauty.

Conducting a Comprehensive Initial Evaluation of Limestone Surfaces

Before commencing the honing process, it is essential to undertake a thorough assessment of the limestone surface. This evaluation encompasses various factors, such as the level of wear, existing damage, and the unique qualities of the limestone being addressed. Professionals typically examine the surface for cracks, chips, and stains, all of which can profoundly influence the honing method selected for the task. A meticulous evaluation ensures that the appropriate techniques and tools are employed, resulting in superior outcomes and safeguarding the integrity of the limestone.

For example, a surface exhibiting minor scratches might only require a light honing, whereas deeper imperfections could demand more intensive approaches. By carefully assessing the condition of the limestone, professionals can determine the appropriate honing pads and tools to utilize, customizing the process to the material’s specific needs. This initial step is also crucial for setting realistic expectations regarding the potential outcomes of the honing process, allowing homeowners or contractors to plan their efforts accordingly.

Examining Various Techniques for Honing Limestone Surfaces

A multitude of honing techniques is employed across the UK, each distinctly tailored to address the specific condition and type of limestone being treated. The most commonly used method involves diamond-encrusted honing pads, which efficiently grind away the surface layer to reveal a fresh, smooth finish. This technique is particularly effective for limestone that has lost its luster due to dullness or scratches, rejuvenating its appearance and restoring its natural brilliance.

In addition to diamond honing, some professionals may opt for a chemical honing approach, using specific acidic solutions to dissolve surface contaminants and stubborn stains. This method requires meticulous care, as improper application of chemicals can lead to further damage to the limestone. Familiarity with these various techniques empowers both professionals and homeowners to make informed decisions regarding the most suitable method for each specific limestone surface, ensuring optimal results.

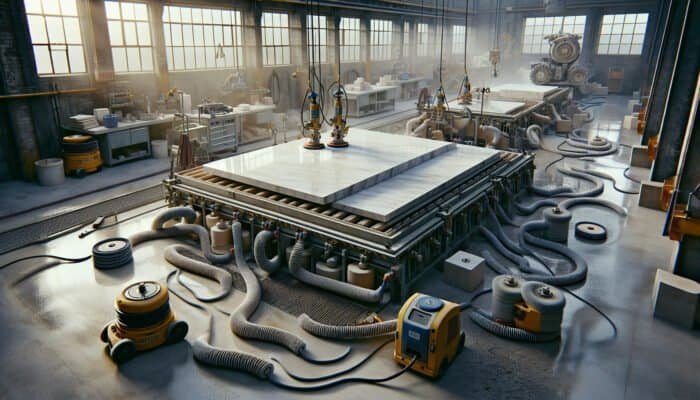

Essential Tools and Equipment for Efficient Limestone Honing Procedures

The tools and equipment utilized in honing limestone across the UK are crucial in achieving high-quality results. Essential items include diamond polishing pads, floor buffers, and vacuum systems specifically designed to minimize dust and debris during the honing process. Selecting the correct grit level for polishing pads is vital, as different grades provide varying levels of refinement to meet specific needs and achieve desired finishes.

For instance, coarse pads (50-200 grit) are utilized during the initial grinding phase, while finer pads (800-3000 grit) deliver the finishing touches that create a polished and refined appearance. Furthermore, employing a high-quality floor buffer with appropriate RPM settings guarantees that the honing process is both efficient and effective. With the right tools and techniques, honing can revive limestone surfaces to their original splendor, enhancing both their visual allure and durability.

Implementing Effective Repair Strategies for Damaged Limestone Surfaces

Repairing damaged limestone is a vital aspect of maintaining both its aesthetic charm and structural integrity. Whether addressing minor chips or significant erosion, using the correct repair methods can greatly extend the life of limestone surfaces, ensuring they are cherished for many years to come.

Identifying Damage on Limestone Surfaces with Precision

Recognizing damage on limestone surfaces requires a discerning eye and a deep understanding of the material’s inherent characteristics. Common signs of damage include visible cracks, chips, and discoloration. For many homeowners, it is essential to conduct regular inspections of limestone surfaces for these indicators, especially in areas that are exposed to severe weather conditions or high foot traffic, where wear and tear may be more pronounced.

In addition to visual inspections, homeowners can perform tactile checks by feeling for rough patches or uneven areas. Not all damage is readily apparent; underlying issues may manifest as surface-level problems. Therefore, recognizing the common types of limestone damage can be crucial in determining when professional intervention is required, ensuring timely repairs are initiated before further deterioration occurs.

Implementing Reliable Repair Techniques for Limestone

Numerous methods are available for repairing damaged limestone, each tailored to address specific types of damage. For minor chips and cracks, epoxy fillers are often used to restore the surface. This technique involves cleaning the affected area, applying the filler, and smoothing it out to blend seamlessly with the surrounding limestone. Once the filler has cured, the area can be polished to match the original finish, effectively concealing the repair and preserving the stone's integrity.

In cases of more extensive damage, such as large cracks or areas that have eroded, a more complex repair procedure may be necessary. This often includes cutting out the damaged section and replacing it with a new piece of limestone that closely matches the original material in both composition and appearance. Precision in executing such repairs is essential to ensure a cohesive aesthetic, preserving the structural integrity and overall beauty of the building for future generations.

Choosing Quality Materials for Effective Limestone Repairs

The materials selected for limestone repair are just as critical as the techniques employed. High-quality epoxy fillers are favored for their superior bonding strength and durability, ensuring that repairs endure over time. Additionally, when replacing larger sections of limestone, it is vital to source matching stone from reputable suppliers to guarantee consistency in color and texture, thus maintaining the overall aesthetic of the structure.

Moreover, applying sealants post-repair is essential for protecting the limestone from future damage. These sealants establish a barrier against moisture, stains, and environmental pollutants, thereby extending the lifespan of the repair. Opting for eco-friendly sealants can further enhance the sustainability of the repair process while maintaining the visual appeal of the limestone, contributing to environmentally responsible practices.

Proactive Measures to Prevent Future Limestone Damage

Once repairs are completed, adopting proactive measures to avert future damage is imperative. Regular cleaning and maintenance routines can significantly reduce wear and tear on limestone surfaces. Utilizing pH-neutral cleaners specifically designed for limestone is crucial, as harsh chemicals can exacerbate deterioration and lead to costly repairs.

Implementing protective measures, such as applying sealants every few years, can minimize the effects of weathering and pollution on limestone surfaces. Homeowners should also consider installing awnings or overhangs in areas prone to excessive exposure to rain or sunlight, effectively shielding the limestone from the elements. These strategies not only enhance the longevity of limestone surfaces but also preserve their beauty for future generations, ensuring that they remain a source of pride and admiration.

Locating Professional Limestone Services Throughout the UK

Finding the right professional for limestone honing and repair is crucial to achieving exceptional results. With a multitude of services available across the UK, understanding the key factors to consider can significantly streamline the selection process, enabling homeowners to make informed choices regarding limestone maintenance.

Essential Criteria for Choosing a Skilled Limestone Specialist

When searching for a limestone expert, several key criteria should guide your selection process. First and foremost, evaluate their experience and standing within the industry. Seek professionals who have a proven track record in limestone honing and repair, as this expertise directly influences the quality of work performed and the longevity of your limestone surfaces.

Reviews and testimonials from prior clients can offer valuable insights into the reliability and craftsmanship of the service provider. It is also advisable to confirm whether they utilize industry-standard tools and techniques, ensuring a higher level of care and attention to detail during the honing and repair processes. Lastly, inquire about their qualifications or certifications, as these can further validate their expertise in limestone restoration and maintenance.

Highlighting Successful Case Studies in UK Limestone Projects

Examining successful limestone honing and repair projects across the UK can provide both inspiration and confidence when selecting services. Notable case studies include the restoration of the limestone façade at the National Gallery in London, which involved intricate honing techniques to revive the stone’s original beauty, ensuring its continued prominence in the city’s architectural landscape.

Another compelling example can be found in the Cotswolds, where local artisans undertook a significant project to restore the historic limestone buildings of a picturesque village, ensuring that repairs harmonized with the traditional aesthetic while incorporating modern techniques. These projects underscore the importance of skilled professionals in maintaining the integrity of limestone structures and their relevance to local heritage, showcasing the value of investing in quality restoration services.

Understanding the Cost Factors for Comprehensive Limestone Services

The costs associated with limestone honing and repair can differ significantly, influenced by factors such as the extent of damage, the type of limestone, and the complexity of the required work. Homeowners should anticipate expenses related to both labor and materials, with prices for professional services typically ranging from £25 to £100 per hour, depending on the intricacy of the project and the level of expertise involved.

For larger projects, such as comprehensive restorations or installations, costs may increase; however, this investment is often justified by the preservation of valuable architectural features that enhance property value. It is wise to obtain estimates from multiple service providers, as this can help establish a reasonable price point while also offering an opportunity to assess each provider’s expertise and approach to limestone care.

Engaging in DIY Projects for Limestone Honing and Repair

For homeowners interested in hands-on projects, embarking on DIY limestone honing and repair can be both an attractive and fulfilling option. However, understanding the necessary precautions and techniques is crucial to achieving satisfactory results while ensuring safety throughout the process.

Implementing Essential Safety Precautions for DIY Limestone Projects

Before starting a DIY limestone honing and repair project, it is vital to implement appropriate safety measures. Utilizing protective gear such as gloves, safety goggles, and a dust mask will help prevent injuries from dust and particles generated during honing. This precaution is especially important when working with power tools, which can generate substantial amounts of debris and create potential hazards.

Furthermore, ensuring that the workspace is well-ventilated is crucial for dissipating any fumes from sealants or adhesives used during repairs. Familiarizing oneself with the tools and materials involved is fundamental; understanding their safe handling can minimize potential risks associated with the honing and repair process, allowing for a smoother experience overall.

Key Tools Required for Successful DIY Limestone Projects

To achieve successful results in DIY limestone honing and repair, specific tools are indispensable. A comprehensive set of diamond honing pads in various grits is essential for achieving a smooth finish, alongside a variable-speed floor buffer for effectively applying these pads to the limestone surface.

Other necessary tools include a vacuum for efficient debris removal, chisels for more significant repairs, and quality epoxy fillers for effectively mending cracks and chips. Home improvement stores typically stock these essential items, and investing in high-quality tools will yield better results in the long run. Additionally, having a sturdy work surface and appropriate cleaning products specifically designed for limestone will significantly enhance the overall effectiveness of your DIY project, ensuring a professional finish.

A Comprehensive Step-by-Step Guide to Accomplishing Limestone Honing and Repair

Embarking on a limestone honing and repair project can be straightforward when following a structured approach. Begin by thoroughly cleaning the limestone surface to remove any dirt, grime, or existing sealant that may impede the honing process. A clean surface is vital for achieving the best results and ensuring the longevity of the material.

Next, assess the surface for any damage that requires attention, addressing chips or cracks with epoxy filler to restore its integrity. After allowing the filler to cure adequately, proceed to the honing process using diamond pads, starting with a coarse grit to eliminate scratches and imperfections before transitioning to finer grits for polishing.

Once the honing is complete, clean the surface again to remove any residue and apply a suitable sealant to protect the limestone from future damage. Establishing a maintenance schedule will ensure that the limestone continues to look its best, allowing you to enjoy the fruits of your labor for many years to come while preserving the beauty of your investment.

Strategically Preserving Limestone Following Honing and Repair

After limestone has undergone honing and repair, implementing a robust preservation strategy is crucial to maintain its condition and aesthetic appeal over time. This proactive approach ensures that the limestone retains its beauty and remains structurally sound, emphasizing the importance of ongoing care.

Effective Cleaning Techniques for Limestone Surfaces

Regular cleaning is essential for preserving the exquisite beauty of limestone surfaces. Homeowners should always opt for pH-neutral cleaners specifically formulated for limestone, as acidic or abrasive products can cause irreversible damage. A soft cloth or mop should be used for cleaning, avoiding stiff brushes that may scratch the delicate surface of the limestone.

For stubborn stains, a gentle paste made from baking soda and water can be applied; this mild abrasive can effectively lift stains without harming the limestone. It is also advisable to adopt a routine cleaning schedule, ideally every few weeks, to maintain limestone’s pristine appearance and prevent the accumulation of dirt or grime that can detract from its natural beauty and integrity.

Applying Protective Treatments for Enhanced Longevity of Limestone

Applying protective treatments after honing and repair is crucial for safeguarding limestone against future damage. Sealants specifically designed for natural stone create a barrier that repels water, oils, and dirt, making routine maintenance easier and more effective. Regularly reapplying the sealant every few years can further ensure that the limestone remains protected against staining and discoloration, thus extending its life and visual appeal.

Opting for eco-friendly sealants can enhance the sustainability of this practice, contributing to environmental preservation while maintaining the aesthetic integrity of the limestone. Consulting with professionals regarding the best products suited to specific limestone types can provide tailored recommendations for optimal results, ensuring the longevity of your limestone surfaces.

Establishing a Routine Maintenance Schedule for Limestone Care

Creating a regular maintenance schedule is critical for effectively preserving limestone surfaces. Homeowners should aim to conduct thorough inspections at least biannually, scrutinizing for signs of wear, damage, or staining that may require attention. Following these inspections, a deep clean and reapplication of sealant should be performed as necessary to maintain the integrity of the limestone.

Additionally, monitoring high-traffic areas or surfaces that are frequently exposed to weather-related conditions can help identify issues early, allowing for timely intervention. Incorporating these practices into a consistent maintenance routine will ensure that limestone surfaces remain vibrant, structurally sound, and visually appealing, thereby preserving their charm for generations to come.

Addressing Environmental Considerations in Limestone Preservation

Environmental factors, such as the UK’s unpredictable weather patterns and varying pollution levels, can significantly impact the preservation of limestone. Rain, particularly acid rain, can erode limestone surfaces, while pollutants may lead to unsightly staining and discoloration over time. Therefore, implementing environmental measures, such as creating protective overhangs or using coverings, can mitigate some of these risks and shield limestone from harsh weather conditions.

Furthermore, planting greenery around limestone structures can absorb pollutants and provide a natural barrier against environmental stressors, enhancing the longevity of the limestone. Understanding these ecological dynamics is crucial for effective limestone preservation, ensuring that these structures remain enduring symbols of history and culture.

Utilizing Professional Restoration Services When Necessary

Despite diligent maintenance efforts, there may be instances when professional assistance becomes necessary for limestone repair and maintenance. Homeowners should be vigilant in recognizing signs that indicate the need for expert consultation, such as extensive staining, large cracks, or significant surface wear that may compromise the integrity of the building.

Professional restoration services offer expertise and advanced techniques capable of addressing issues that exceed the capabilities of DIY methods. Regular consultations with limestone specialists can also aid in maintaining surfaces in optimal condition, prolonging their lifespan and preserving the integrity of the heritage they represent. Engaging professionals ensures that limestone structures are cared for with the utmost respect and skill, safeguarding their historical and cultural significance.

Evaluating the Environmental Impact and Sustainability of Limestone Care

As global awareness of environmental challenges continues to rise, honing and repairing limestone sustainably becomes increasingly vital for preserving both the material and the planet. The limestone industry must adapt to these challenges, embracing practices that promote environmental stewardship while maintaining the beauty and integrity of this essential resource.

Implementing Eco-Friendly Honing Practices within the Limestone Industry

Adopting eco-friendly honing practices is paramount within the limestone sector. Techniques that minimize water usage, such as dry honing methods, are gaining popularity, effectively reducing the environmental impact associated with water waste while still achieving desirable results. These methods benefit the ecosystem and align with the growing emphasis on sustainability across various industries.

Additionally, opting for diamond tools that boast longevity and require less energy during the honing process yields superior results while minimizing the carbon footprint of limestone restoration projects. Industry professionals are increasingly focusing on sustainable practices that resonate with broader environmental goals, contributing to the preservation of both limestone and the ecosystems that inhabit it, thus fostering a more sustainable future.

Utilizing Sustainable Materials for Limestone Repairs

The choice of materials for limestone repair significantly influences sustainability. Employing eco-friendly epoxy fillers and sealants with low volatile organic compounds (VOCs) can mitigate harmful emissions throughout the repair process. Sourcing locally quarried limestone for replacements not only supports local economies but also reduces transportation emissions, thereby lessening the carbon footprint associated with repairs.

Moreover, selecting durable materials ensures that repairs are long-lasting, minimizing the need for future interventions and promoting sustainability. As the industry evolves, the use of innovative and sustainable materials is becoming more common, reflecting a commitment to preserving both heritage and the environment for future generations.

The Impact of Limestone Care on UK Heritage Sites

Limestone honing and repair are integral to preserving the rich heritage of the UK. Many historic buildings, monuments, and sites are primarily constructed from limestone, representing a significant aspect of the country’s cultural narrative. By employing sustainable practices, heritage professionals can ensure that these sites remain protected and appreciated by future generations, safeguarding their historical and cultural significance.

In numerous instances, the restoration and maintenance of limestone heritage sites also contribute to local tourism, providing economic boosts while fostering a deeper understanding of history and culture. Consequently, the impact of limestone preservation extends far beyond aesthetics; it plays a vital role in sustaining cultural identity and pride within communities, ensuring that the stories and legacies encapsulated in these structures endure through time.

Anticipating Future Trends in Limestone Care and Maintenance

As the limestone care industry progresses, several emerging trends promise advancements in techniques, materials, and sustainable practices. These trends reflect a growing commitment to improving the care of limestone while addressing environmental concerns and enhancing overall outcomes.

Embracing Technological Innovations in Limestone Care Practices

The future of limestone honing and repair appears poised for transformation with the introduction of technological advancements. Advanced machinery, such as robotic polishing systems and automated cleaning devices, is increasingly finding its place within the industry. These technologies offer unparalleled precision and consistency compared to manual methods, enhancing the overall quality of limestone restoration and maintenance.

Moreover, integrating digital monitoring systems designed to assess limestone surfaces is emerging as a valuable tool. These systems allow professionals to track the condition of limestone over time, identifying potential issues before they escalate into significant problems. As technology continues to advance, the potential for improved limestone care and preservation becomes increasingly promising, paving the way for more efficient and effective practices.

Shifts in Material Use Towards Sustainability in Limestone Care

Within the limestone industry, a notable trend is the growing shift towards utilizing more sustainable materials. Innovations in biodegradable sealants and environmentally friendly repair compounds are gaining traction, addressing consumer demands for greener solutions that align with contemporary environmental values. This shift benefits the environment while also resonating with the increasing awareness of sustainability within the construction and restoration sectors.

As businesses adapt to these changes, the availability and promotion of these eco-friendly materials will likely increase, encouraging more professionals to embrace sustainable practices in their work. This trend represents a significant step towards ensuring that limestone care remains both effective and environmentally responsible, securing a harmonious balance between heritage preservation and sustainable development.

Emerging Environmental Regulations Affecting Limestone Care Practices

The UK is witnessing a shift in environmental regulations that are influencing limestone care practices. Stricter guidelines surrounding emissions and the use of certain materials are prompting businesses to adopt greener methods and processes. This evolving regulatory landscape encourages the adoption of environmentally friendly practices, aligning with broader governmental and societal objectives for sustainability and responsible resource management.

Professionals in the limestone industry must remain informed about these changes, adapting their practices to comply with new regulations while also seizing the opportunity to innovate. Through these efforts, the future of limestone care promises a more sustainable and environmentally responsible approach, ensuring that this valuable resource continues to be cherished and preserved for generations to come.

Frequently Asked Questions about Limestone Care and Maintenance

What is the process of honing limestone surfaces?

Limestone honing is a meticulous finishing process that smooths and refines the surface of limestone, enhancing its natural beauty while preparing it for effective sealing and protection against future damage.

Why is it essential to maintain limestone properly?

Regular maintenance of limestone is crucial to prevent wear, staining, and structural damage, ultimately ensuring its longevity and preserving the beauty of historic buildings and structures.

Can homeowners repair limestone surfaces on their own?

Yes, homeowners can conduct minor repairs on limestone surfaces using appropriate tools and materials. However, for extensive damage or intricate repairs, professional assistance is recommended to ensure proper restoration.

What tools are necessary for DIY limestone repairs?

Essential tools for DIY limestone repair include diamond honing pads, a reliable floor buffer, quality epoxy fillers, and pH-neutral cleaners. Proper safety gear is equally important to ensure a safe working environment.

How frequently should limestone surfaces be cleaned for optimal care?

Limestone surfaces should ideally be cleaned every few weeks to prevent the accumulation of dirt and staining, with deeper cleaning and sealant applications performed biannually for optimal maintenance.

What are common indicators of damage on limestone surfaces?

Common signs of damage on limestone surfaces include visible cracks, chips, discoloration, and rough patches. Regular inspections can help identify these issues early, allowing for timely repairs and interventions.

Which types of sealants are most effective for preserving limestone?

Eco-friendly sealants with low volatile organic compounds (VOCs) are highly recommended as they effectively protect limestone from staining while minimizing environmental impact, ensuring sustainability in preservation efforts.

How long does a typical limestone repair take to complete?

The duration of limestone repair can vary based on the extent of damage and the techniques employed, but most repairs typically take anywhere from a few hours to a couple of days to complete.

What are the typical costs associated with professional limestone services?

Costs for professional limestone honing and repair services in the UK typically range from £25 to £100 per hour, depending on the extent and complexity of the work required for the specific project.

Are there eco-friendly practices that can be implemented in limestone care?

Yes, sustainable practices include using biodegradable cleaning products, employing water-efficient honing methods, and sourcing local materials for repairs, all contributing to environmentally responsible limestone care.

The Article Limestone Honing and Repair: Expert Techniques first found on https://www.abbeyfloorcare.co.uk

The Article Limestone Honing Techniques for Expert Repair appeared first on https://fabritec.org

The Article Limestone Honing Techniques for Expert Restoration Was Found On https://limitsofstrategy.com